Our most frequently asked question is, “How do I have this done on the concrete in my home, or place of business?”

Please visit our Contractor Locator to find a local contractor to perform the work for you.

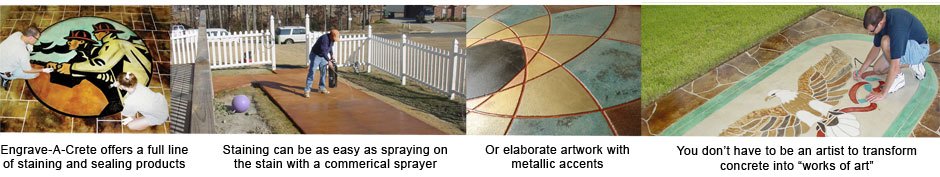

The Engrave-A-Crete® System consists of several combined processes that remodel concrete to produce a pleasing appearance. Briefly, a deep penetrating acrylic or chemical/acid stain is used to transform the color, then a permanent, precise, pattern is engraved (cut) INTO the hard concrete with our patented concrete engravers. The Engrave-A-Crete® Process is NOT a topping or overlayment that could chip off. For more information, be sure to visit the What is Concrete Engraving? page.

Engrave-A-Crete® is unique in the industry because we engineer, manufacture, and distribute the equipment. We have dedicated ourselves to the development of new systems as well as the continuous improvement of our existing machines.

We think this is answered by a quote from the Sydney, Australia newspaper, the Blacktown City Sun.

“INNOVATION seldom goes hand in hand with practicality, sophistication usually sits uncomfortably with durability and the best hardly ever costs the least.”

Nicely said and it continues…

“However, an extraordinary concept has recently been introduced to the homemaker’s market, a revolutionary new process called Engrave-A-Crete® which can turn the common and all-too-boring looking cement driveway, outdoor patio, garage floor, indoor cement slab, garden path and pool contour into an attractive design feature.”

Wait until they see our KaleidoCrete System… Combined, the two systems are magnifico!

Using our technology, ordinary concrete can be remodeled to look like brick, tile, polished marble, flagstone, fieldstone, ashlar slate, cobblestone, geometric designs, corporate logos, or themed designs. Classic circular, arched or straight patterns that look either brand new or with a long history can be engraved into existing concrete. Check out the Photo Portfolio as well as the Decorative Concrete Artistic Expression page.

Driveways, floors, parking lots, entries, walkways, basements, pool decks, patios, restaurant and retail floors–any concrete residential, commercial or municipal. Many homes, office buildings, restaurants, stores, fast food establishments, and convenience stores have Engrave-A-Crete® inside and out.

Pricing depends on your location, the pattern, the size of the job, the number of colors, and a few other factors. Generally we suggest that you charge more than products like overlayments and toppings. The perception of price and quality go hand in hand. The complete Engrave-A-Crete® process sells in a price range of $3.00 to $6.00 per square foot for an average driveway. Prices are higher ($5 to $8 per square foot) in some areas where they have good marketing and sales techniques. You should charge more for small areas like patios and sidewalks or borders. In the Engrave-A-Crete® Operator’s Manual, there is a collection of several pricing guidelines from current installers.

Yes, in the last few years— China, Nigeria, Indonesia, Mexico, Canada, Sri Lanka, Botswana, Ghana, Kenya, Uganda, and several other African countries Australia, France, Italy, Armenia, Bahamas, Barbados Bermuda, Qatar, U.A.E. , Croatia, Czech Republic, Grande Cayman, Finland, Greece, Hong Kong, New Zealand, India, Israel, Iraq, Ireland Jamaica, Malaysia, Netherlands, Kuwait, Norway, Turkey, Azerbaijan, Oman Philippines, Saudi Arabia, Taiwan, Trinidad, UK Japan, S. Korea, Tunisia, Virgin Islands, West indies, Brazil, Sudan, Morocco, Germany, plus many other countries.

Recently we have sent equipment, concrete stains, sealers and supplies to our wonderful customers in these countries — we can get it to your door step also.

It’s very important to keep those costs low, and that’s one of the great benefits of this system. Materials and supplies, which includes concrete coloring stain or dye, clear seal coat, roller covers, concrete preparation supplies and other miscellaneous items all cost about $.25 to $.85 per square foot for exterior jobs, and $.40 to $1.35 per square foot for interior floors. Diamond blades cost about 2 to 8 cents per square foot depending on the aggregate hardness, operator techniques, and depth of cut.

Engrave-A-Crete® can supply you with what we feel are the best products for the industry. The line of Concrete Resurrection products is a compilation of what we feel are the best materials available. They are clearly labeled to eliminate the guess-work of suitability for interior and exterior concrete. Concrete Resurrection products span from economical materials to high end coatings, as well as cleaners and sealer removers.

Since nothing is impervious to the sun’s UV rays, everybody’s colors change. Fade? Maybe a little. Many times a color actually becomes darker. Changes in the color of a stain outside are very slow and span many years, especially when they are routinely maintained with a clear sealer. Keep in mind, the routine maintenance of decorative concrete projects can provide you with a continuous revenue stream.

There is no thickness added. The grooving process cuts the concrete to give an appearance of a grout line and that gives the look of depth and texture.

- Thoroughly clean the concrete.

- If any, do repairs and crack filling.

- Stain or dye the concrete to the chosen color or colors.

- Many times (not always) apply a coat of sealer for stain protection during the engraving process.

- Set up the concrete engraver for the design and cut the grooves.

- Clean up, touch up, and apply a protective clear coat to the surface.

- Utilize and reference the Engrave-A-Crete Technical Support FAQ.

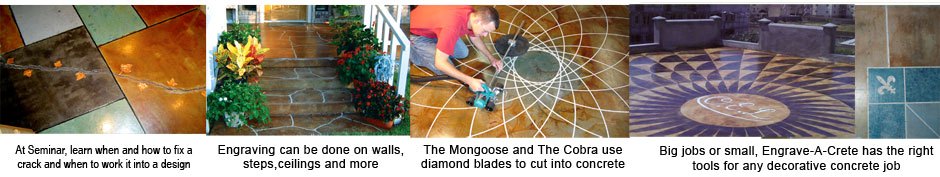

Widening a crack and/or filling it with a special super-duper epoxy compound generally does not work. Smearing a crack with polymer cement won’t fix a crack either. That crack is going to remain in the concrete, period! The best thing is to very carefully fill a crack with a flexible product (depending on choice of stain). A crack can be tolerated if it’s hidden and disguised in the pattern. On badly cracked or poor quality concrete, we often engrave a design such as flagstone or cobblestone which can disguise the cracks in the cuts. Many times very ugly concrete makes beautiful stones.

The Engrave-A-Crete® process can be used on walls, ceilings, and concrete steps including risers and treads.

There are proven methods that you can use to change the color of ordinary gray concrete. Penetrating acrylic and Reactive Acid Chemical (RAC) stains can give a wide variation of looks, from a solid uniform color to a marbled, variegated, aged or antique appearance.

It’s a coordinated action where the operator is guiding and propelling the engraver and in turn the engraver and the tracking system are guiding the operator. The pattern is cut into the concrete with a unique diamond saw blade mounted in the engraving machine.

Yes. Interior work is the main business of many operators.

From several days to several weeks or several months. It depends on how small or how massive the project is. Some projects are 100 square feet and some are 100,000 square feet or more. A lot depends on whether you focus on residential or commercial work. Typical operators find the average job size is between 1000 to 5000 square feet.

Size is unlimited. The patterns can carry on and repeat thousands and thousands of feet.

Many times one person can do the entire process, but on certain types of patterns or large projects temporary laborers can be employed to assist in completing the project.

As they say…”this isn’t rocket science”. A person can self train with the aid of the Mastering Concrete Engraving DVD and machinery manuals. Also available is the comprehensive Decorative Concrete Training Seminar, where you get hands-on experience using the stains, sealers and equipment. You’ll fast track through basic to advanced techniques and learn valuable tips and tricks of the trade.

A major advantage of the Engrave-A-Crete® Systems – most of the time, if you find it necessary to leave a job site during operations, it’s no problem. If it rains or gets too hot to work, just quit. It won’t damage the finished product. Simply return when you are able and start where you left off. This is very important due to things that are beyond your control such as the weather, illness, golfing, or major sporting events! Some phases, like the application of stain or sealer should be finished, but generally it’s no big deal to simply stop work.

With periodic maintenance the surface will look substantially the same years after the installation. With no maintenance, engraved bricks naturally take on an antique or used brick appearance over the years. Brick, cobblestone, and flagstone that looks like it has a long history is desired by many.

Depending on the customer’s wishes and products used, there are multiple ways to change the color and appearance of an existing job.

Engrave-A-Crete® bricks, tiles and cobblestones are guaranteed to never come loose. How could they? The pattern is cut INTO the concrete. The pattern will last as long as the concrete because it IS the concrete.

Although it may not be practical, concrete can be engraved on the coldest or the hottest days. The concrete surface temperature needs to be between 50 and 90 degrees for the application of stains and sealers.

The clear sealers help protect the concrete to make it last longer and withstand the weather better. The process uses moisture barrier but vapor permeable protective clear sealers. By keeping water, salt and deicers out of the concrete, it is less likely to spall or delaminate. Machines have been operating successfully for many years in northern States and Canada.

Every homeowner, business, builder, remodeler, pool builder, landscaper, shopping center, bank, plaza, office building and municipality or government facility is a potential customer. Nearly any concrete can be remodeled. Every floor, driveway, sidewalk, walkway, entrance, patio, and courtyard, that’s now concrete or to be poured in concrete, is a potential Engrave-A-Crete® masterpiece. Ultimately, the amount of business that you generate is up to you.

A person can self train with the aid of the Mastering Concrete Engraving DVD and machinery manuals. Also available is the comprehensive Decorative Concrete Training Seminar, where you get hands on experience using the stains, sealers and equipment. You’ll fast track through basic to advanced techniques and learn valuable tips and tricks of the trade.

When you come to visit us for our Training Seminar, there is no obligation to purchase when you visit. We welcome your comments, questions, and ideas at any time. We are here to help. For technical assistance call us at 1-800-884-2114.

You may purchase your equipment using any of several different methods. We accept Visa, MasterCard, Discover, American Express, cash, cashiers check and wire transfer. We happily accept business or personal checks, but the bank requires we wait 7 to 10 business days for the check to clear before shipping your equipment.

We ship via UPS or LTL freight (less than truckload freight is quoted by multiple carriers).

Engrave-A-Crete® is not a franchise. It is unlawful for us to try to control or distribute territories. With no restrictions, you may farm as large an area as you like. If you decide to move you can take your equipment and business with you. We do not collect royalties or franchise fees and do not require you to purchase supplies from us.

Yes, Engrave-A-Crete® warranties engraver components for 1 year. Warranties cover manufacturing defects. Except for normal wear, tear, and usage, we will fix, repair or replace the equipment and /or parts as we determine. Items that we don’t manufacture but resell as a convenience (such as air compressors) are covered by the manufacturer’s warranty.

Currently Engrave-A-Crete® is the sole US manufacturer, but please visit our Distributors page to see a list of current domestic and international distributors and resellers.

Depending on several things like temperature and humidity, with few exceptions, stains and sealers require a 30 to 45 day cure time. Concrete hydrates during cure. As it cures, moisture dissipates from the slab. If it is sealed too soon, the water vapors may build up and push the stain and sealer off. How soon a pattern can be engraved or cut also depends on several things like temperature, humidity, aggregate type, and the type of cut. You should wait at least 7 days before decorative engraving.

The Engrave-A-Crete® Systems use specially designed diamond blades to cut simulated grout lines. Blade widths are available from 1/16″ to 3/8″ wide to accommodate your customer’s design specifications. We recommend cutting at a depth of 3/32″ which is between 1/16″ and 1/8″. The engravers have the ability to engrave up to 1/4″ deep.