Ten Second Color Acetone Based Stain

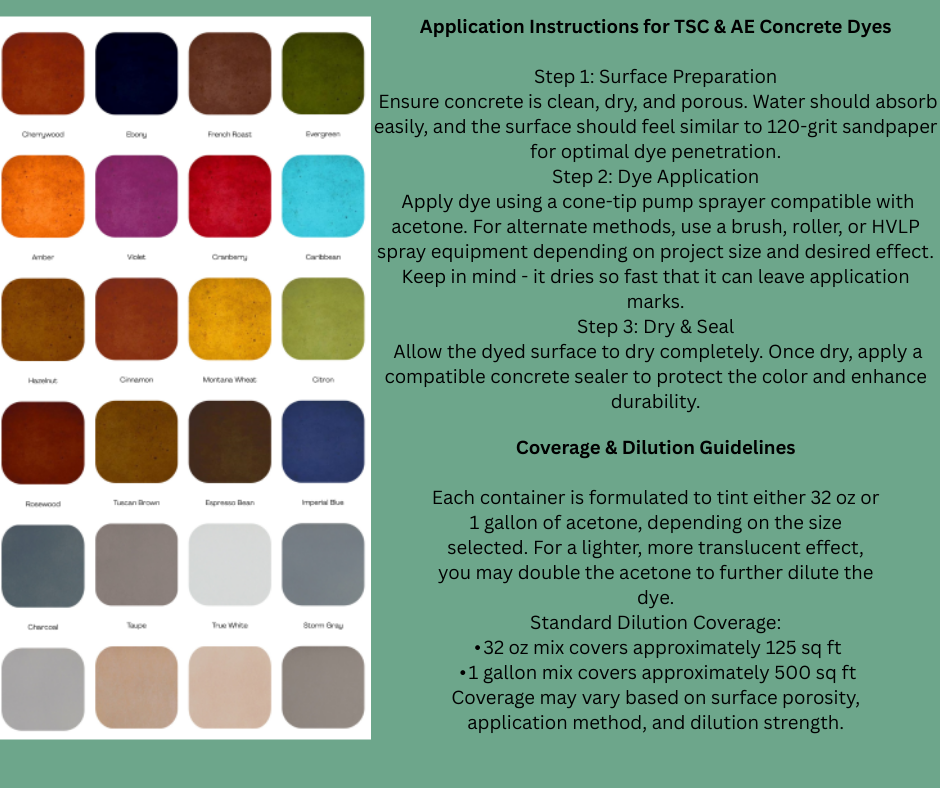

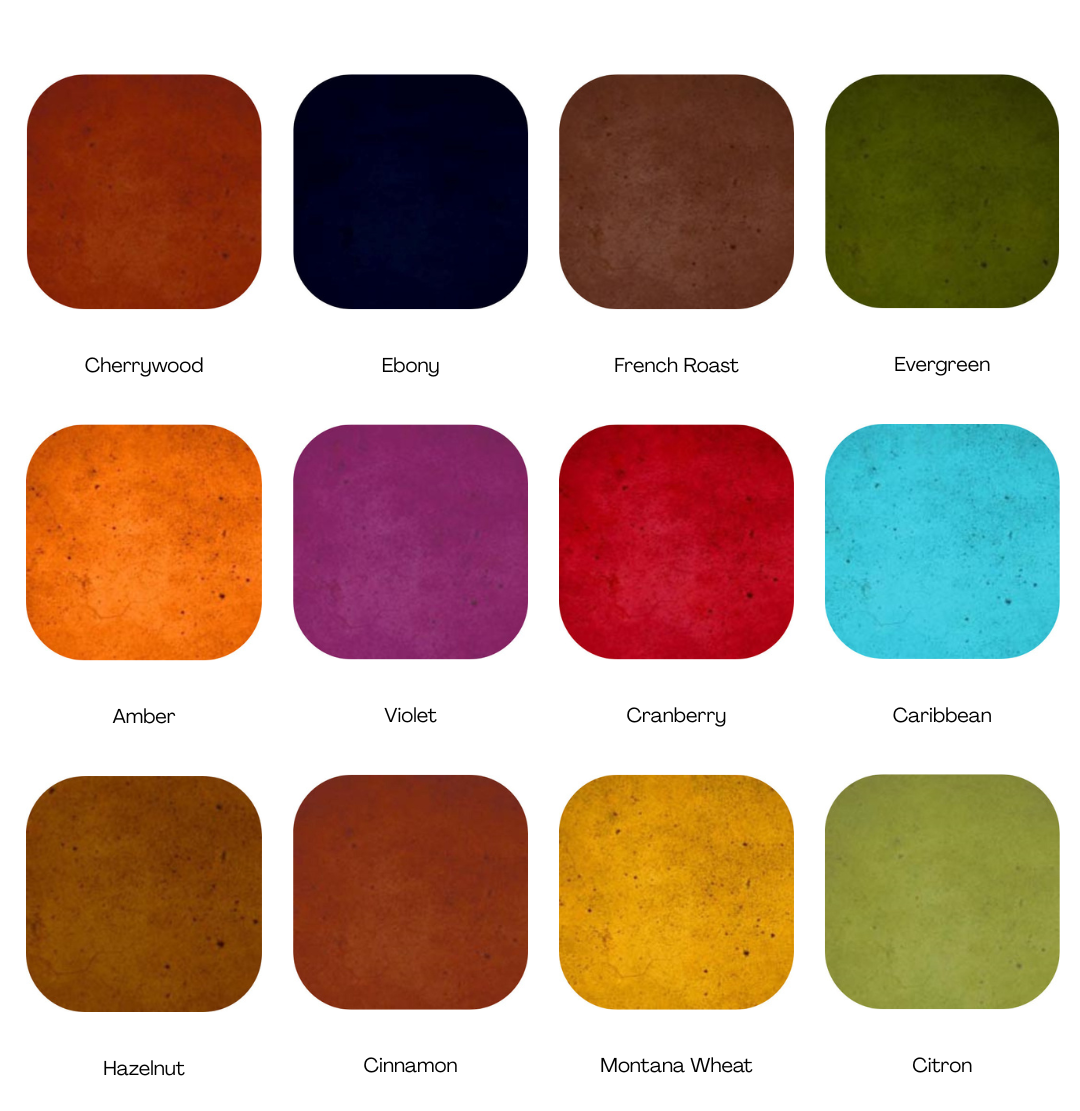

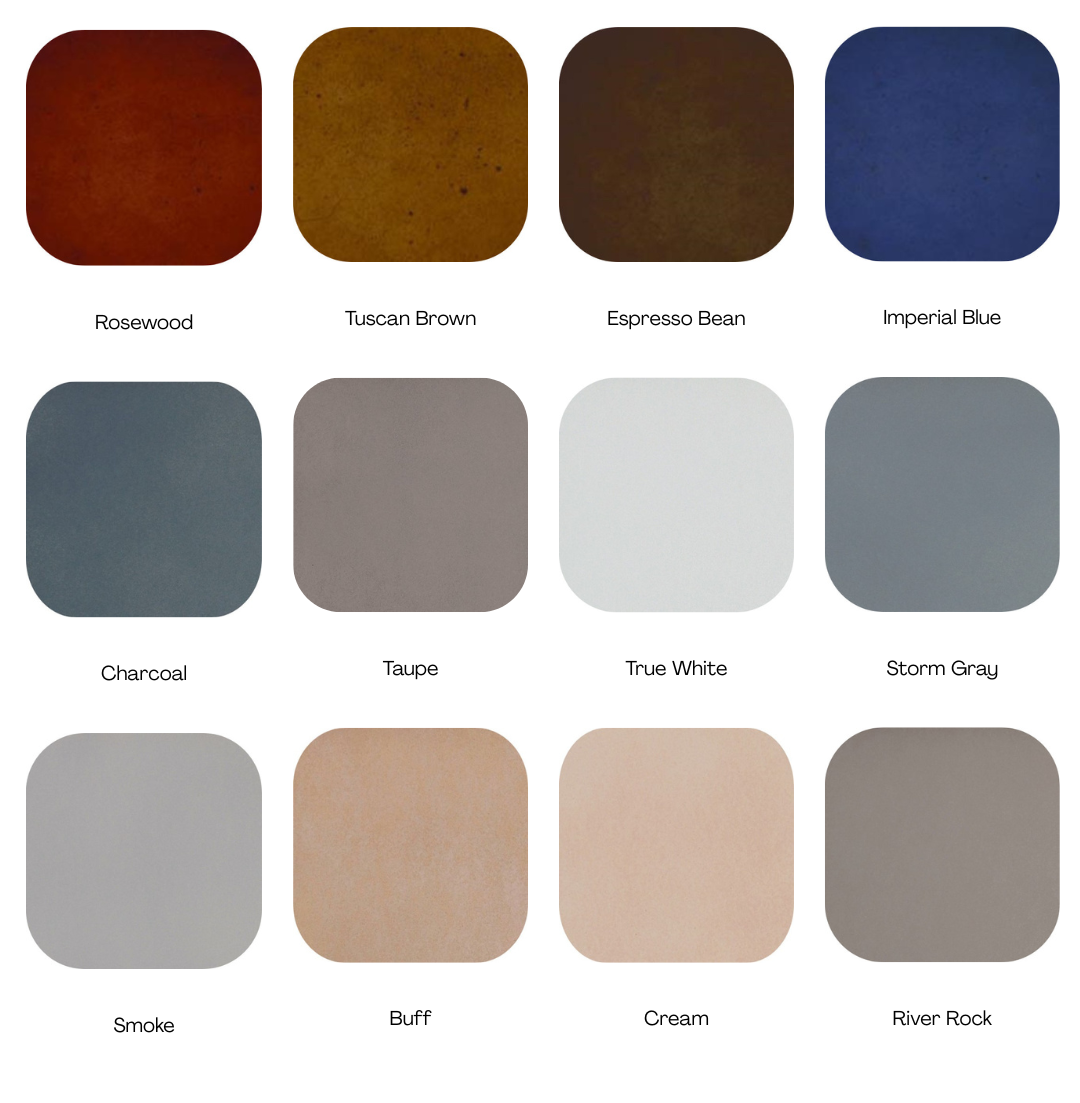

Ten Second Color™ (TSC) and Active Elements Speed Color (AE) are penetrating dyes to color concrete and other cementitious surfaces. When properly applied, they create beautifully mottled effects similar to acid stain in a matter of seconds without the wait time required by acid, saving you time and money. TSC and AE are translucent dyes, and colors can be combined into countless variations and hues, or layered for unique effects. Simply add required amount of acetone and go! For interior and exterior use.

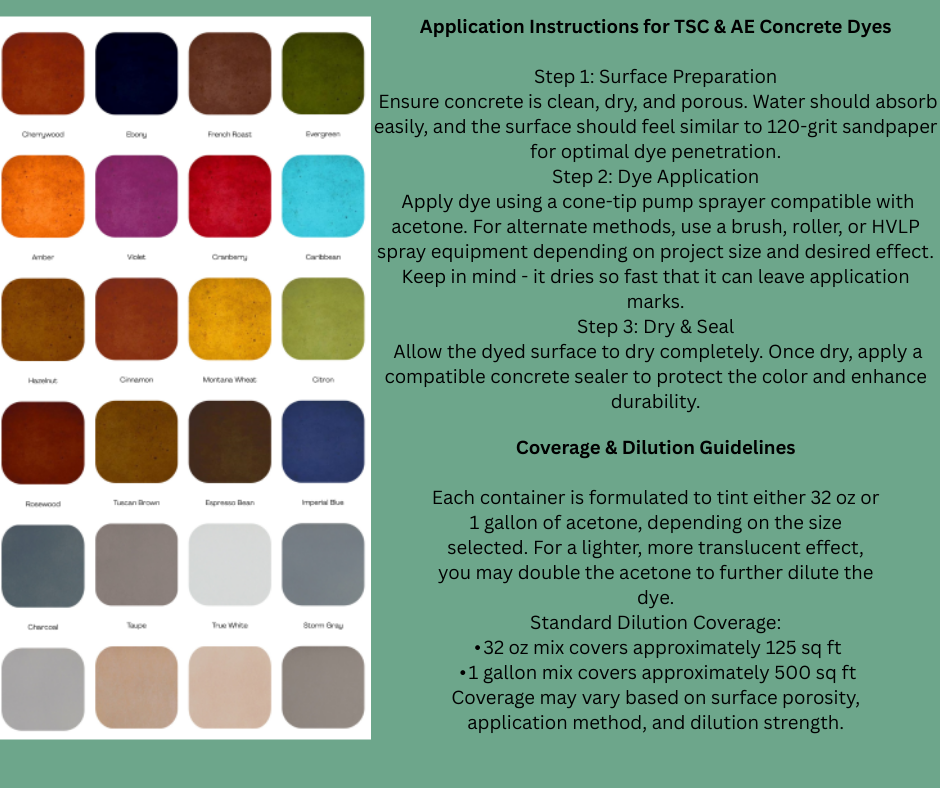

MUST ADD ACETONE! This is for the pigment to color the acetone. Acetone must be purchased locally. The one quart is enough pigment to color 32 ounces of Acetone to make a total of 32 ounces of product. You must add the acetone. One gallon size is 24 ounces of pigment - you must add at least 1 Gallon of acetone. You may dilute the stain with up to 50% more acetone for a lighter shade.

One quart TSC Dye covers an average of 100-150 sq ft.

One gallon TSC Dye covers an average of 400-600 sq ft.

Coverage variations depend on concrete surface porosity and amount of material applied.

Color Test- Apply a test sample of TSC Dye in an inconspicuous area of the floor to verify color. Use the same application method for the test spot as what is planned for the entire floor.

Mixing

***ACETONE MUST BE ADDED TO DYE**

32 OUNCES CONTAINER: MIX 32 ounces of acetone to under filled jars of TSC dye..

Step 1: If needed, remove all paint and/or sealer from the surface using CR-590 Paint & Sealer Remover.

Step 2: If the surface has an oily or greasy film OR if CR-590 Paint & Sealer Remover was used, scrub the surface using CR-580 Degreaser.

Step 3: (REQUIRED) Use mechanical means to open up the pores of the concrete (Grinding, Black Pad, Sanding Screen or Coatings Removal Pad for Interior Slabs or Pressure Washer for Exterior Slabs) or apply CR-765 Surface Prep & Etch at a dilution ratio of 4 parts water to 1 part Surface Prep & Etch. Scrub in with a stiff bristle broom. When the fizzing action stops, rinse the surface with water. Do not allow the Surface Prep & Etch solution to dry on the concrete. If a more porous surface is needed repeat Step 3. An interior floor’s surface texture should feel similar to 120 grit sand paper.

Step 4: (REQUIRED) If acid etching, you must apply CR-585 Surface Neutralizer (dilution of 8 oz in 5 gallons water) using a stiff bristle brush or broom to scrub in the neutralizing solution then rinse with water.

CAUTION: Acetone is Flammable - Do not use any form of electrical equipment to mix the dye with the acetone. Refer to MSDS for exposure limitations and safe handling practices.

Application: Concrete substrate MUST be clean and dry before applying TSC Dye. Apply TSC Dye with a cone tip pump sprayer that is compatible with acetone. Keep the tip approximately 24 inches from the surface. Apply in a uniform circular motion, not allowing product to puddle in low spots. The concrete surface should appear wet for just a few seconds when applied properly. TSC Dye can also be applied with a brush, roller or HVLP spray equipment. Properly evaluate each job to determine the best method of application.

TSC Dye may leave residual dye on the surface after each application. Vacuum loose dye prior to sealer application. The use of water to clean and remove loose dye is NOT recommended.

When spraying TSC Dye, protect surroundings with masking paper or masking plastic.

It is strongly recommended that a clear sealer be applied as a top coat for abrasion and UV resistance. It is recommended that a non-skid / skid reducer be utilized when sealing exterior surfaces.

Seal surface with a low viscosity, sprayable sealer. Use appropriate sprayer and tip per individual sealer instructions. If applying with a roller, do not overwork sealer as it may reactivate the dye.

Floor Finish –When using a floor finish, allow sealer to dry and completely cure for 3-4 days.

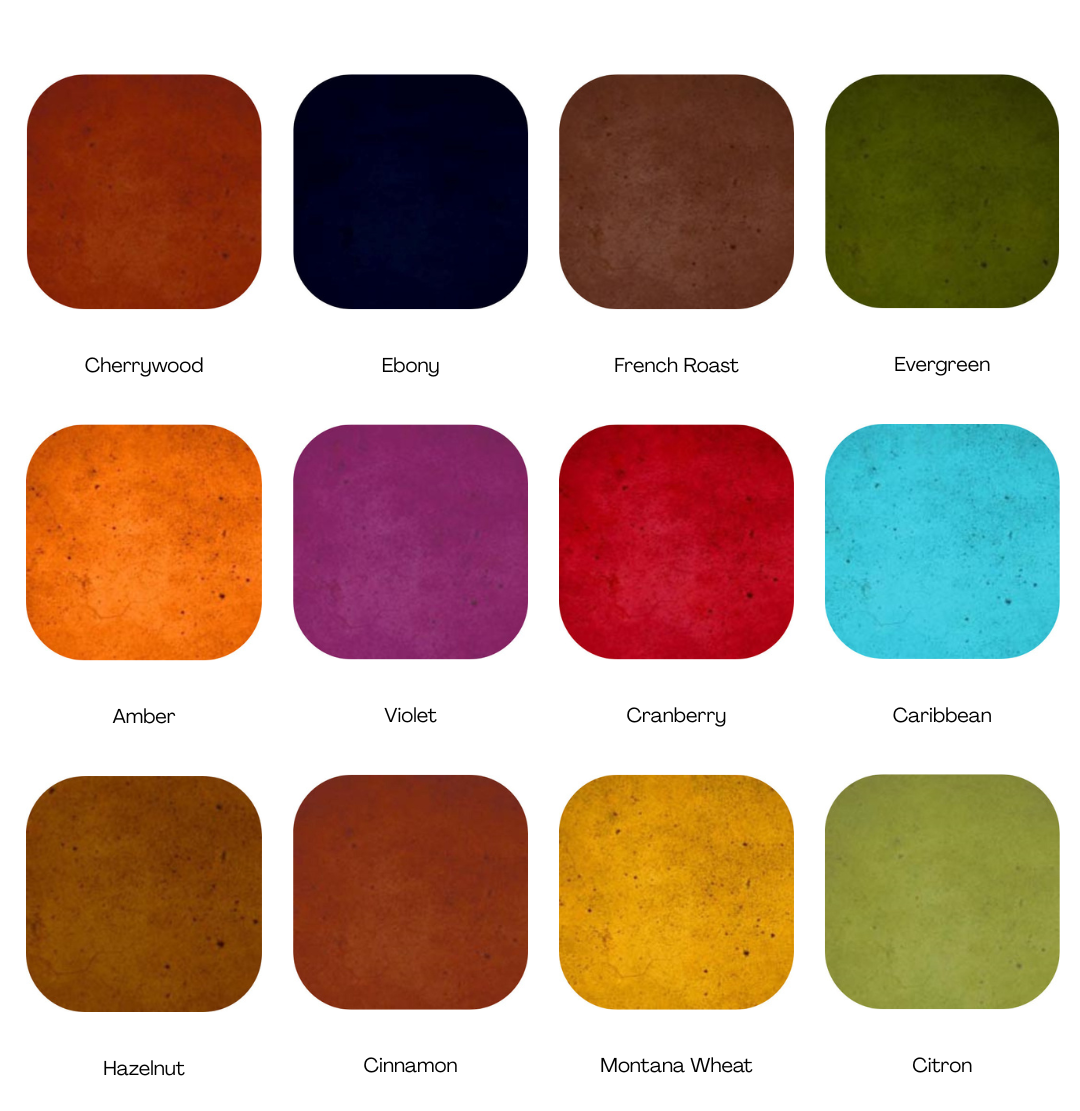

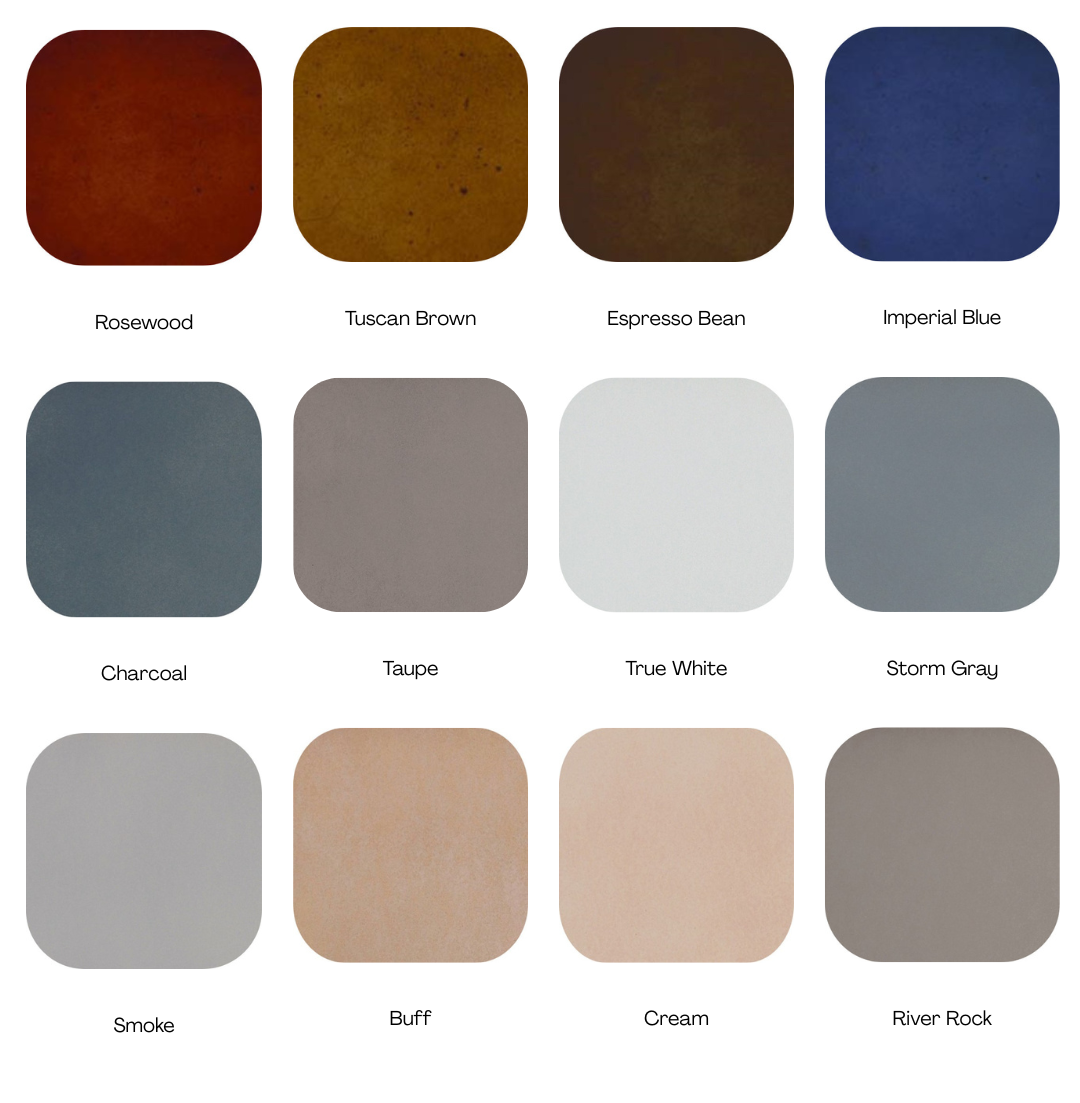

Choose options