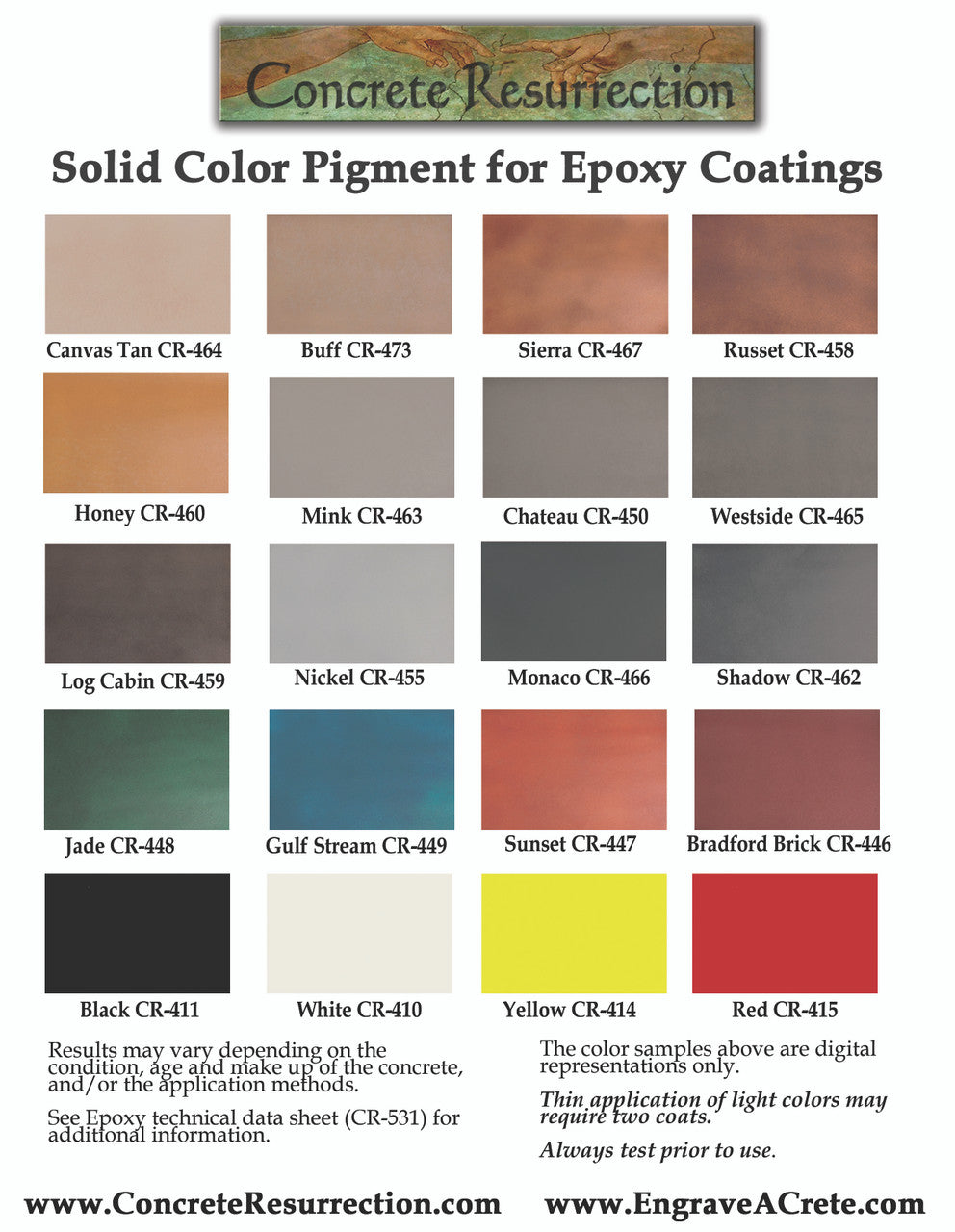

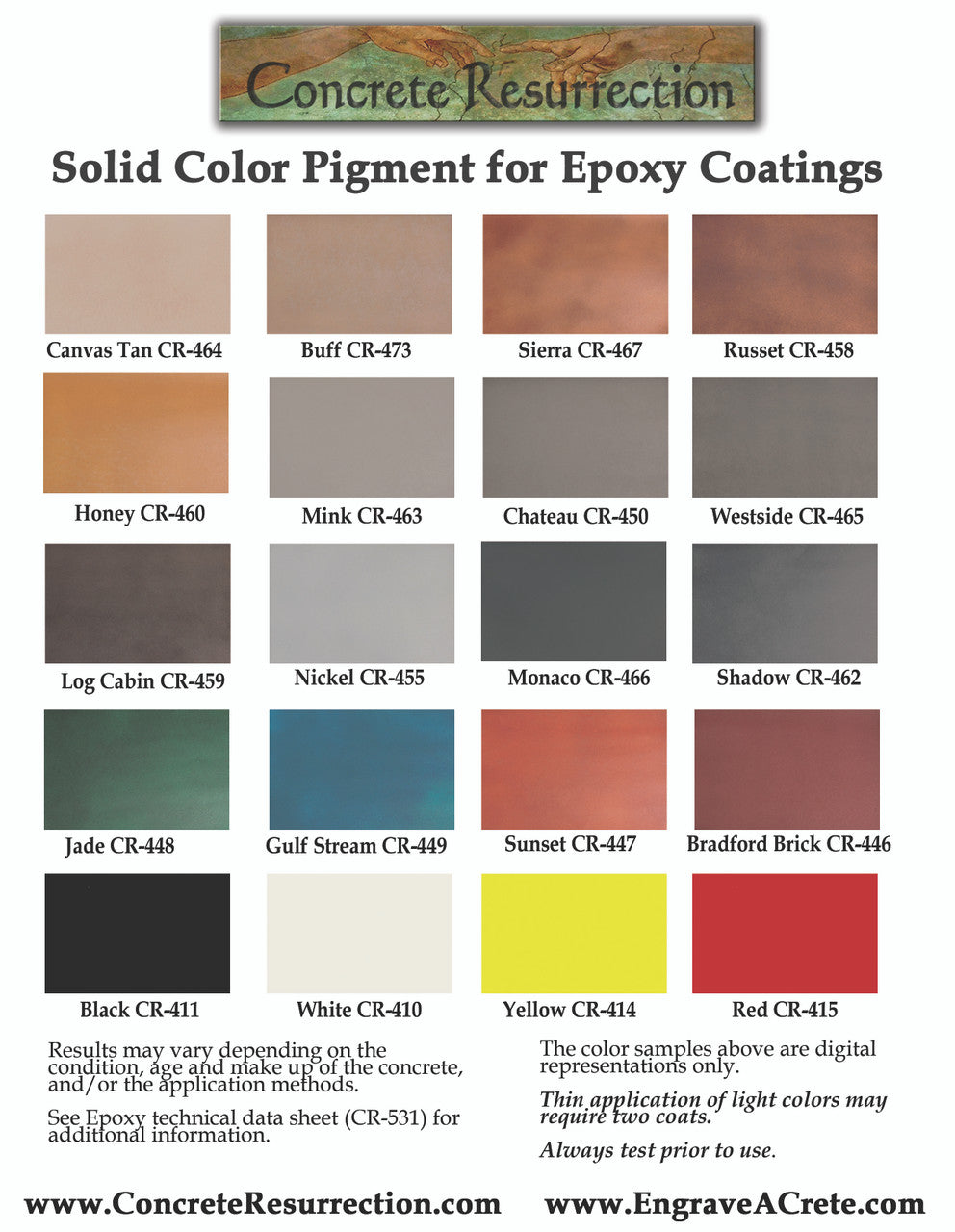

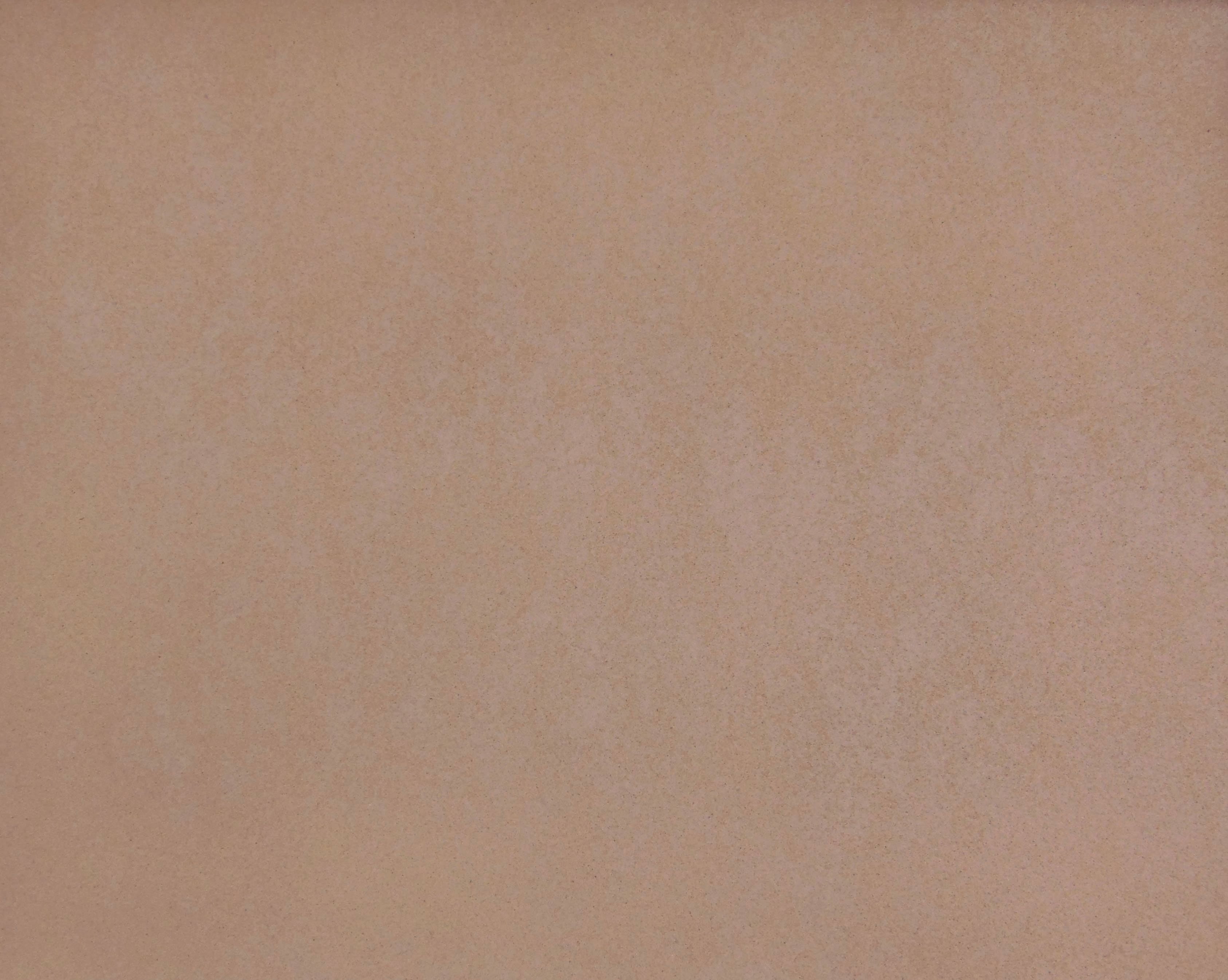

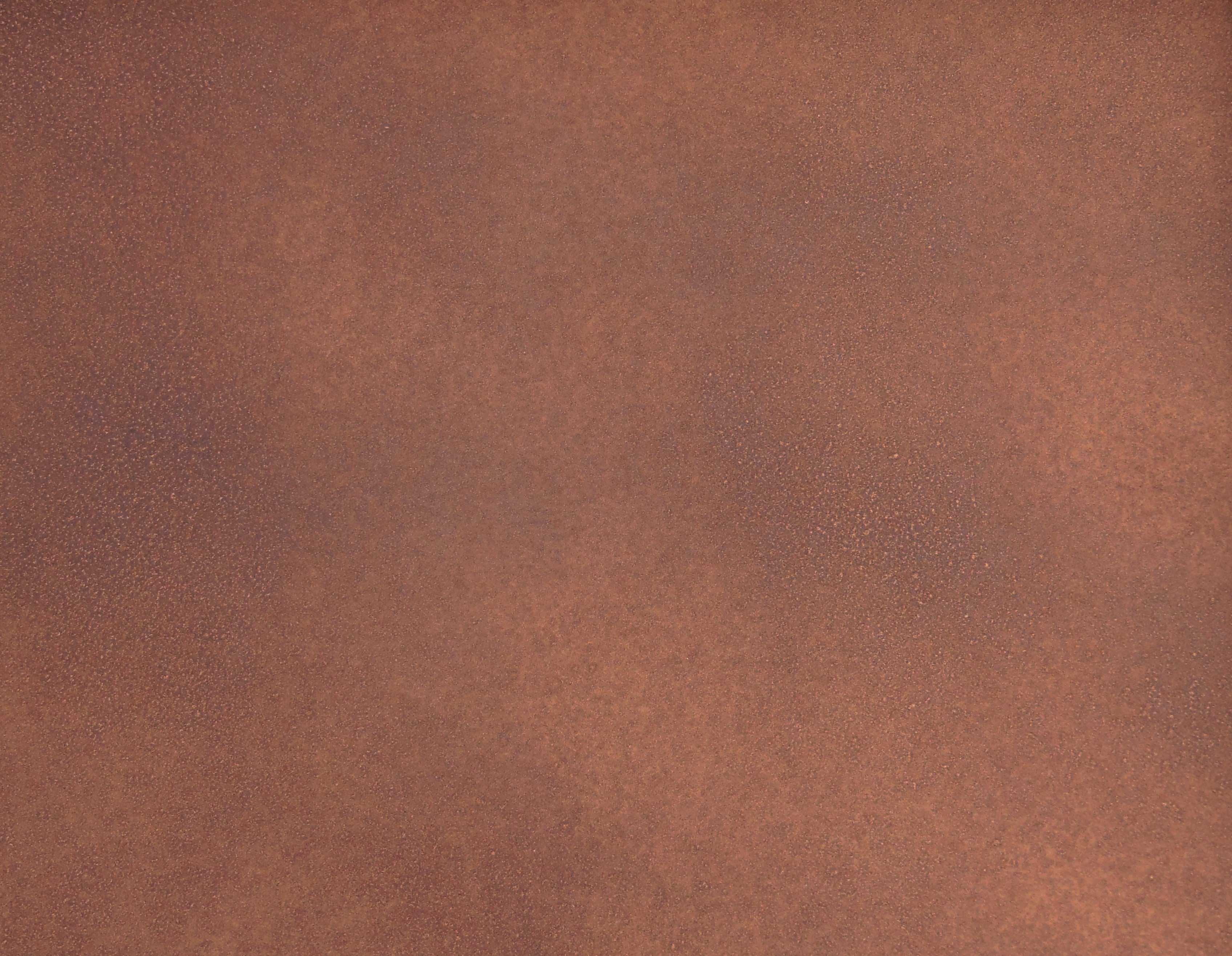

Solid Color Epoxy Pigment

Solid Color pigment for Epoxy. Add one container of pigment to 3 Gallons of Part A Epoxy (or until desired opacity is achieved).

Solid Color Epoxy Pigment is ideal for…..

- Floors and counter tops

- Base coat for metallic epoxy

- Filling cut lines

- Chip floors

- Art projects

Mixing Instructions

When mixing epoxy pigments, add the appropriate amount of pigment into the resin (part “A”) and mix completely using a paint mixer on a low speed drill. When desired color is achieved, follow the directions above for adding and mixing in the hardener (part ”B”). It is critical to have an exactly portioned mixture, which has been prepackaged for you to eliminate any guesswork or measuring.

After combining the two components, use a paint mixer on a low speed drill for 2 minutes to completely mix the components. Be careful to not whip air into the mixture, and be certain to scrape the sides and bottom of the can to combine all molecules. Incomplete mixing or an off balance mixture will result in a coating that will remain soft.

Application Recommendations

The epoxy can be applied at a rate of 3 to 8 mils thick, using a roller, squeegee or trowel within the usable pot life time frame, as well as the recommended temperature and relative humidity guidelines listed in the Technical Information section.

While applying keep a wet edge to prevent streaking. It is recommended to work in sections usually using control joints as dividers to ensure proper application results. Do not allow to Puddle!

For a thicker build and bolder color pour contents out in a long trail for application. Spread with Notched squeegee or gauge (wider squeegee is recommended), Spread product evenly over area. Flatten the poured out trail into place, as it self-levels. Back roll with a 3/8” roller or mohair roller or smooth using a speed squeegee or loop roller. (rollers should be premium quality with phenolic core and 18” wide is recommended for larger areas)

Choose options