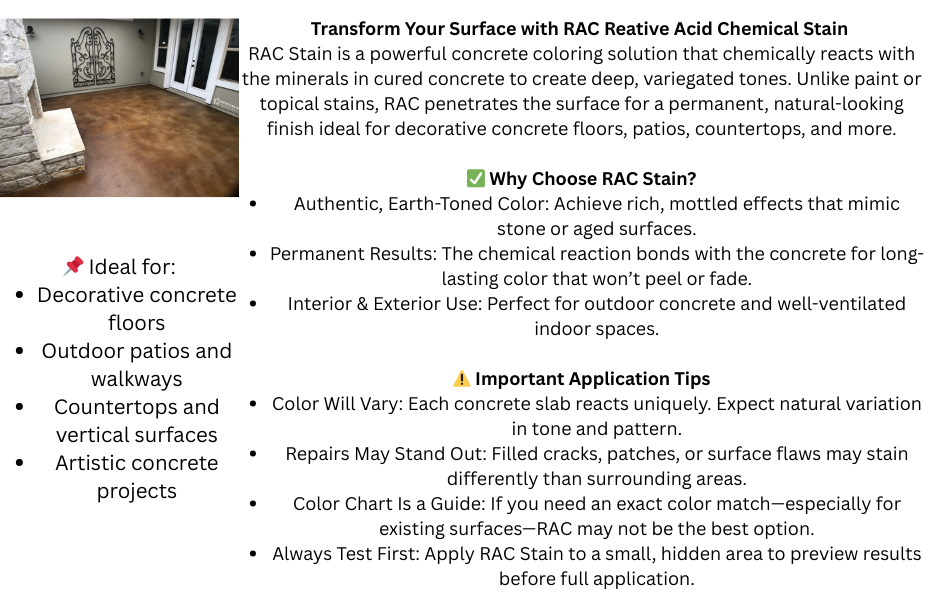

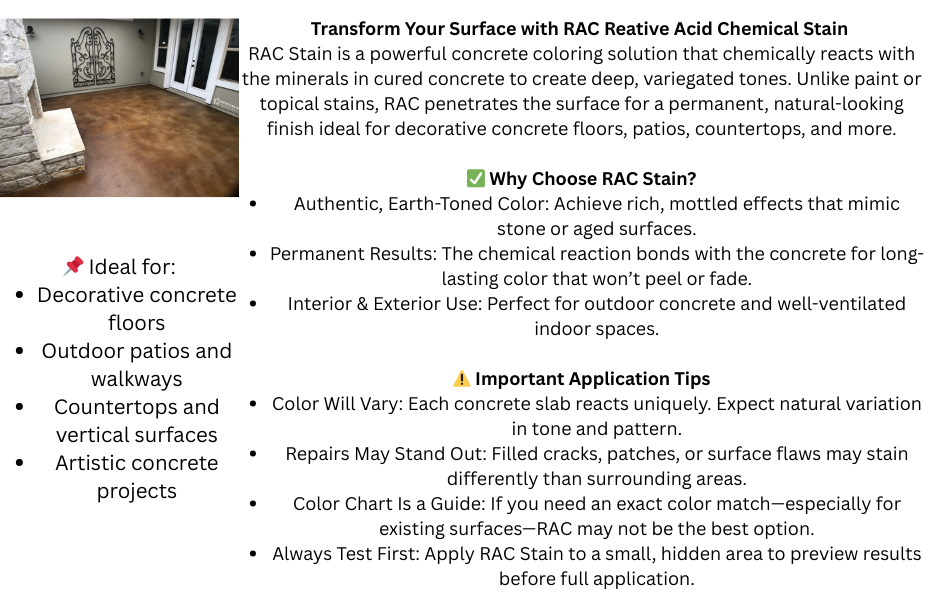

Reactive Acid Chemical (RAC) Concrete Stain

Elevate your concrete surfaces with Reactive Acid Chemical (RAC) Concrete Stain, the perfect solution for infusing classic elegance into domestic and commercial spaces. This professional-grade acid stain performs a remarkable transformation, reacting with the minerals in your concrete to create stunning, vibrant colors that are both translucent and variegated. The outcomes are unique to each slab, as variables like texture, age, and dilution ratio dictate the final appearance—ensuring your concrete becomes truly one-of-a-kind.

RAC Stain delivers a sophisticated, marbleized effect that showcases the inherent character of the slab. Unlike traditional paints, which merely coat the surface, this acid stain penetrates deeply to physically alter the color of the concrete, ensuring longevity without bonding issues. With its UV stability, this stain is perfect for both interior and exterior projects, making it a versatile choice for any environment.

100 - 200 square feet per gallon. Coverage varies with the surface texture of the concrete, temperature of the concrete, and ambient conditions.

DILUTION: Dilution will vary square foot coverage. When a lighter color is desired, use – Color Extender or water as a reducing agent. Mix at a ratio of 1 Part Color Extender to 1 Part RAC Stain when you need to keep the acidity higher.

Concrete must be clean and free of all dirt and contaminants. Concrete floors must be open and porous prior to applying Active Elements - Concrete Acid Stain. Oil and grease must be removed prior to stain application using Degreaser. Paints and sealers must be removed prior to stain application using our paint and sealer remover - or by mechanical means.

- Interior floors – The required minimum preparation is scrubbing using a floor machine (buffer) with a black pad, grit brush or sanding screen.

- Exterior surfaces (broom finished) – The required minimum preparation is pressure washing.

Equipment must be constructed of plastic or other non-corrosive material. The stain can be applied using a plastic pump sprayer, brush, rag, or sponge. Wash equipment thoroughly after use with water.

NEUTRALIZATION

After the full stain reaction has occurred neutralize the concrete by scrubbing the surface with Concrete Resurrection Neutralizer (8oz in 5 gallons water). A stiff bristle brush or broom should be used to scrub in the neutralizing solution. Use a wet vacuum to collect residue and wastewater. Dispose in accordance with local, state, and federal regulations.

**This product may only be used on fully cured concrete. Allow a minimum of 28-45 days of cure time after the concrete placement to allow ample time for the concrete to completely hydrate.

A minimum of 24 hours of drying time (after the stain has dried to the touch) is required before applying a clear sealer.

It is strongly recommended that a clear sealer be applied as a top coat for abrasion and UV resistance.

It is recommended that a non-skid / skid reducer be utilized when sealing exterior surfaces.

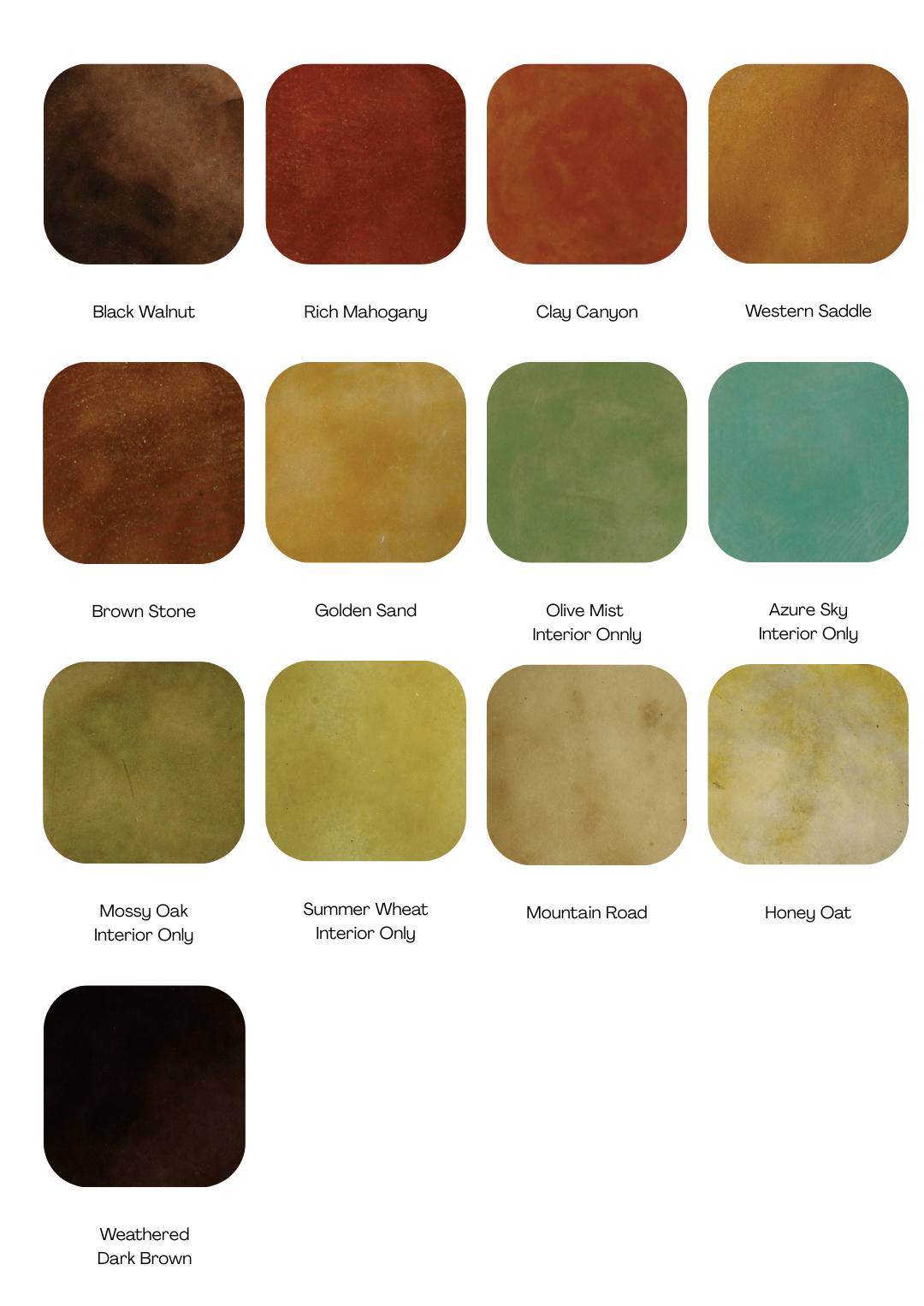

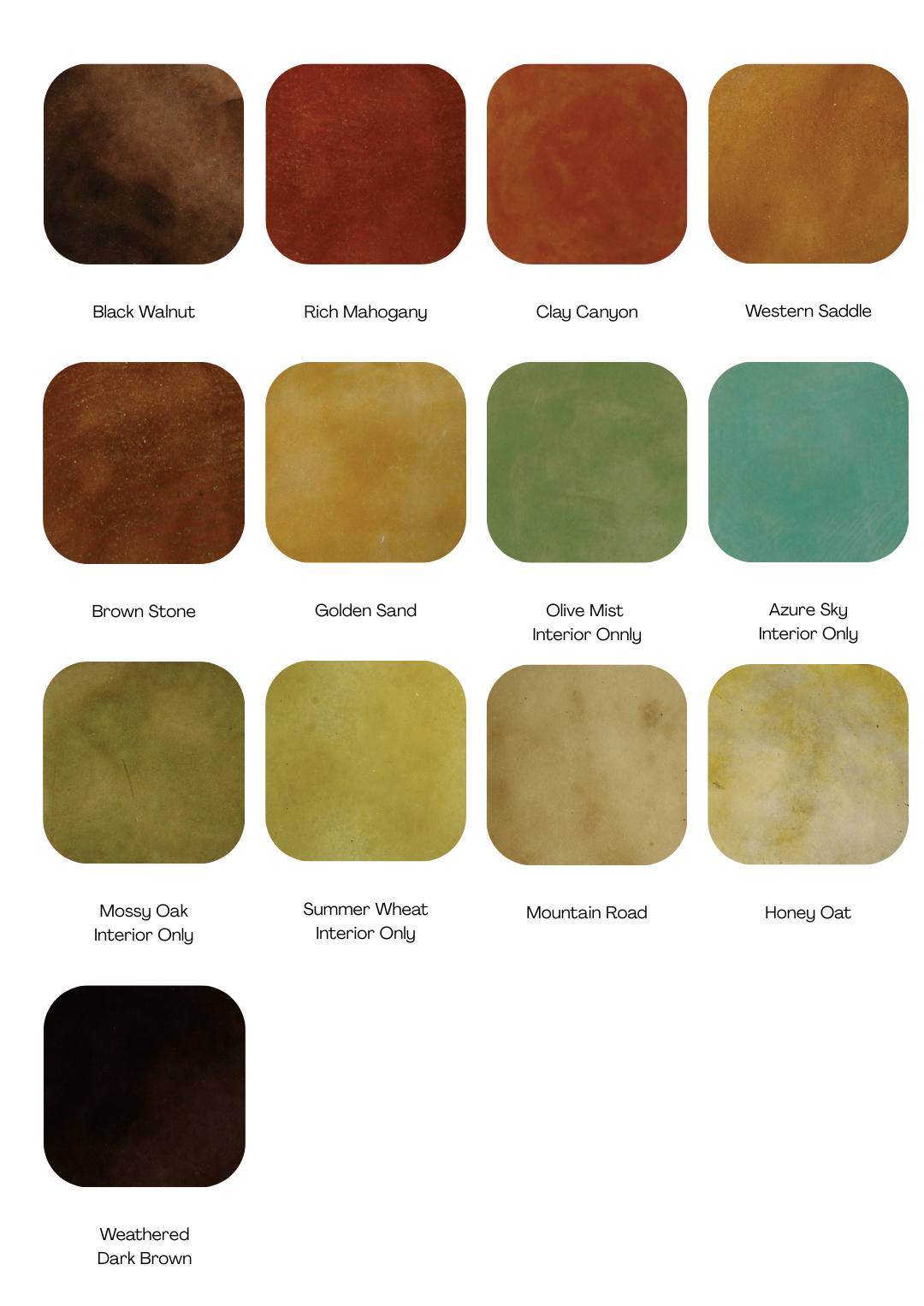

Choose options

Media grid